“Gaia” or the Living Planet in a Living Universe.

Natural Resource Management Versus Bioenvironmental Management:

The human decision to use a material enables it to be labeled a resource.1 The total flow of a material from its state in nature through its period of contact with man to its disposal can be termed a resource process.2 Efforts made to achieve orderly and sustainable use of Natural Resources can be termed as the Management of Natural Resources. The attempt to minimize the impact on the environment of Natural Resource exploitation is termed as Bioenvironmental Management. The goal of Natural Resource Management is oriented more towards development and change rather than the preservation of nature. As a matter of simple economic sense, resources are managed in order to keep them available. It was the growing awareness of the inter-dependence between the living and nonliving components of the natural world that has led to the more dynamic concept of BioEnvironmental Management.3 “It is recognized that it is the Bioenvironmental systems of the planet which provides resources and that any resource process must be rationally managed in order to ensure a sustained yield – preferably one which is capable of due increase, but in which the existence of limits is recognized.”4 Thus, it can be safely said that Natural Resource Management is the process of ensuring the sustainability of resource exploitation. On the other hand, Bioenvironmental Management is the process of ensuring the sustainability of the life-supporting environment.

There are two main avowed aims of Bioenvironmental Management. The first being the reduction of the degree of stress, upon an ecosystem, from contamination or overuse. The second is the pursuit of short-term strategies that preserve long-term options while retaining a degree of flexibility. Irreversible environmental change is anathema to Bioenvironmental Management and is exactly what it seeks to avoid at all costs. However, economic exploitation is not derided as it is recognized that natural resources need to be used in order to ensure the survival of the human race. However, it is this very long-term survival that has prompted Bioenvironmental Management.

Conservation broadly means using without using up. Pollution control is playing an expanding role in the Conservation Movement. However, it is seldom realized that pollution is the end product of a destabilizing process of the biosphere on a global scale. The proponents of “Spaceship Earth Economy” as an alternate to the present “Cowboy Economy” are still far away from the concept of “Gaia” or the Living Planet in a Living Universe. While concepts may differ it is no longer avoidable to realize the fact that rank and short-term exploitation has to be stopped immediately.

The contrast between the population-resource relationships of different types of countries allows the construction of regional classification.5 Pakistan lies in the type “D” category or most unfortunate group. Here there is no deficiency of appropriate technology. Rather it is not communicated to the “bewildered poor.” The population puts pressure upon resources and is growing at alarming rates. Are we already classified as an MSA (Most Seriously Affected), the subgroup within this group? China is an example of an escape from this category. Can we emulate the example of our great neighbor? With the requisite communication of the absolute necessity of employing Bioenvironmental Management and a clear “Way Ahead,” the answer is YES!

Rain Water Harvesting:

Definition:

Water Harvesting refers to the collection and storage of rainwater and also other activities aimed at harvesting surface and groundwater, prevention of losses through evaporation and seepage and all other hydrological studies and engineering interventions, aimed at conservation and efficient utilization of the limited water endowment of a physiographic unit such as a watershed.

1 I. G. Simmons 1974.

2 Firey 1960.

3 Bennett and Chorley 1978, Holling 1978.

4 I. G. Simmons The Ecology of Natural Resources 1974.

5 Zelinsky 1966.

In general, water harvesting is the activity of direct collection of rainwater. The rainwater collected can be stored for direct use or can be recharged into the groundwater.

Rain is the first form of water that we know in the hydrological cycle, hence is a primary source of water for us. Rivers, lakes, and groundwater are all secondary sources of water. At present, we depend entirely on such secondary sources of water. In the process, we forget that rain is the ultimate source that feeds all these secondary sources and remains ignorant of its value. Water harvesting means to understand the value of rain and to make optimum use of rainwater at the place where it falls.

Need for Water Harvesting:

We get a lot of rain, yet we do not have water. Why? Because we have not reflected enough on the value of the raindrop. Rainfall usually occurs during short spells of high intensity. Because of such intensities and short duration of heavy rain, most of the rain falling on the surface tends to flow away rapidly, leaving very little for the recharge of groundwater. This makes many parts of the Country experience lack of water even for domestic uses.

Ironically, even Cherrapunji in India, which receives about 11,000 mm of rainfall annually, suffers from an acute shortage of drinking water. This is because the rainwater is not conserved and is allowed to drain away. Thus it does not matter how much rain we get, if we don't capture or harvest it we will remain without it when required.

This highlights the need to implement measures to ensure that the rain falling over a region is tapped as fully as possible through water harvesting, either by recharging it into the groundwater aquifers or storing it for direct use.

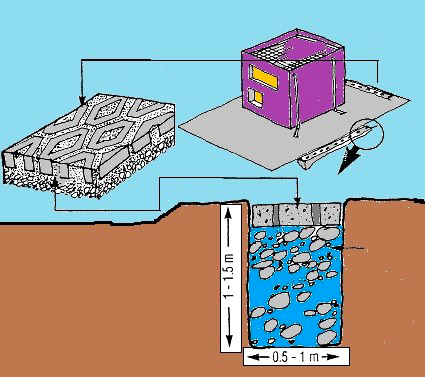

Like most other things, we have managed to make Rain Water Harvesting a mockery of correct implementation. Expensive, Fiber Glass, and PVC Water Tanks have been purchased at inflated rates and installed through mutually beneficial mechanisms to provide Water that is hot in Summers and cold in Winters as well as susceptible to Carcinogenic influences from the material used. I have installed a Pre-Cast, Concrete Ring Water Tank in both Rural and Urban Locations as a pioneering effort during a prolonged period of Drought as well as an intervention to ensure Irrigation Water Supply in Mountainous areas.

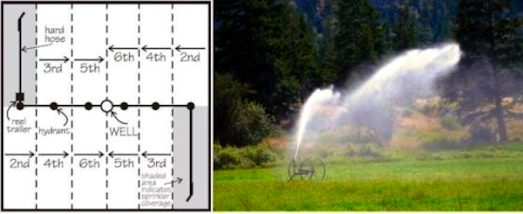

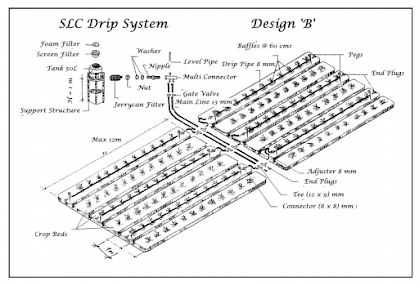

Surface Rain Water Harvesting with Mobile Engine; Pump and Rain Gun in Mung, Haripur, Hazara.

Roof-Top Water Harvesting. National Center for Rural Development, Chak Shahzad, Islamabad.

9 ft height x 5 ft dia x 2 units, Pre-cast RCC Well Rings with Simple Sand/ Gravel Filter.

Earthquake Proof Rain Water Harvesting Holding Tank, Designed for Azad Kashmir. Mule Portable, Modular Fiber Glass Form Work for In-Place Concrete Pouring.

Gender Concerns:

Women play an important role in agriculture and food production in developing countries. They are the dominant labor force in agriculture and make a crucial contribution through engaging themselves in all agricultural activities from the preparation of the soil to post-harvest operations. The development of rural women and encouraging their full participation as equal partners in the social and economic mainstream is one of the greatest challenges being faced by most developing countries today.

Labor migration, especially from the mountain areas, is common in many developing countries, including Pakistan. Whilst the men leave the village to work in towns and cities – or even abroad – the women are left to do all the work needed at home. This both increases their workload but also empowers women to undertake tasks they never have done before.

NOTE FOR RECORD:

COLLABORATIVE MEETING ON WATER HARVESTING: ICIMOD & IUCN/ ERNP:

17 – October – 2000

ISLAMABAD.

Water Harvesting for Survival:

Hazrat Sheikh Qutb Ud Din Bakhtiyar Kaki دحمت اللہ علے , the successor to the Chisti Mantle of Hindustan encouraged Sultan Iltutmish, the Shamsi Malik (Slave Dynasty) to build the Hoaz e Shamsi, The Shamsi Malik’s Water Tank. This red sandstone tank was built to improve the water supply of the expanding City of Delhi. The tank covered an area of 100 acres and provided water for both domestic and irrigation purposes. Ibn e Battuta in his Travels in Asia and Africa, 1335 – 1354 CE, mentions thus. “The inhabitants of Delhi take their supply of drinking water from the Hoaz e Shamsi. It is fed by rainwater and is about two miles long and a mile broad. When the water on the sides of the tank gets dried up, sugar cane, cucumber, sweet calabash, melons and watermelons are grown in it. This was taken to signify an act executed for the public good and far more meritorious than military conquests.”

Years after the death of Sultan Iltutmish, he appeared in a dream to Hazrat Sheikh Nizam ud Din Auliya دحمت اللہ علے saying that his salvation had been assured by his building of this tank. A small mosque called Auliya Masjid was built there and remains to this day. In front of this mosque there are two slabs of sandstone, which designate the place at which Sultan ul Hind, Hazrat Ghareeb Nawaz, Khwaja Moin ud Din Chisti دحمت اللہ علے and Hazrat Sheikh Qutb Ud Din Bakhtiyar Kaki دحمت اللہ علے are said to have prayed together for the success of the venture.

A consultative meeting on the promotion of water harvesting in Pakistan, for domestic and small-scale irrigation, was held in Islamabad on October 17th, 2000. The meeting was arranged by the International Union for the Conservation of Nature (The World Conservation Union) through the aegis of the Environment Rehabilitation in N.W.F.P. (now KP) and Punjab (IUCN/ ERNP) on the behest of the Sustainable Water Harvesting Project, International Center for Integrated Mountain Development (ICIMOD). Water Harvesting is the collection of run off for productive purposes.

The consultative meeting was very well attended by various National and International experts working in fields closely related to the subject. The Federal Secretary of the Ministry of Food, Agriculture and Livestock (MINFAL), Dr. Zaffar Altaf chaired the meeting. Prof. Suresh R. Chalise of the Mountain Natural Resources Divisions of ICIMOD was the chief speaker and was ably assisted by Dr. Salim A. Sial, his Assistant Coordinator.

I had the honor of being included amongst such an august gathering of Professionals. The looming water crisis and timely measures that could be taken to alleviate the attendant misery that is likely to exacerbate in the coming years was the chief concern of the meeting. The most impact was made by the slide on deglaciation or glacial retreat in the Himalayas, shown by Prof. Chalise. Dr. Zaffar Altaf (Secretary MINFAL) captured the spirit of the exercise by declaring that “Water is a flowing Problem and cannot be dealt with harshly, do not confront water!”

The main messages to emerge from the meeting were as follows:

Clarity in Water Policy, on behalf of the Government, is extremely important.

Dissemination and availing of water harvesting, soft technology is facilitated by Policy.

It is necessary to Establish, Promote, and Strengthen Capacities of Water Users Associations.

A Research, Demonstration, and Training Center that works with the close participation of local user groups is required.

At present, there is no clear Policy for Support of Water Harvesting in Mountainous Areas.

There is a need for a dialogue to identify Policy intervention.

Water Harvesting Micro Projects should:

➔ Cater to Participatory Management.

➔ Address Gender Concerns.

➔ Have built-in Conflict Resolution procedure.

➔ At present, there is a 30 % Water Shortage in Pakistan’s Agriculture Sector.

➔ Technology for water harvesting should include indigenous practices.

➔ Technology must be in service to mankind and should serve more, not less.

Rules of thumb to test Technology:

➔ Probability.

➔ Possibility.

➔ Scientific certainty.

At present, there is inequitable water supply and pricing between affluent urbanites and under privileged rural folk.

The meeting went on to discuss practical water harvesting measures such as:

➔ Plastic lined Tanks.

Under shade to reduce evaporation.

Source: Springs/ runoff.

Benefit: Rs. 15,000.00 to 30,000.00 per kanal (vegetables).

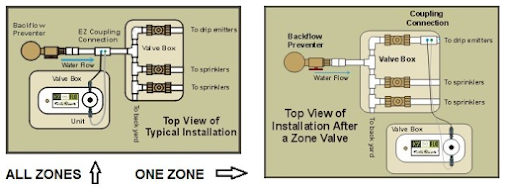

Roof Top Harvesting System.

Ferro Cement Jars with 2,000-L capacity.

A 5-6-member family requires 12,000 L per anum.

Built-in initial flushing.

Underground jars can be used to prevent evaporation.

Thatch Roofs can be used for water harvesting with plastic sheet cover and spout to collect water.

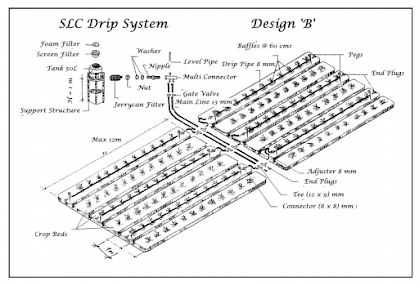

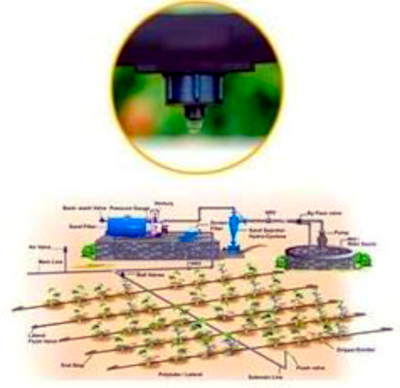

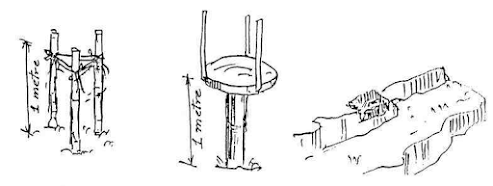

Micro sprinklers and drip irrigation systems can be fabricated locally for cost reduction.

Small, raised tanks can be used for gravity drip irrigation.

Roadside tanks can be made to collect runoff.

Sand and gravel filters should be used at the inlet to exclude sediment.

Runoff diversion channels with check dams and storage tanks on both sides can be used for irrigation.

Small dams with log outlet check valves can be used to control the outflow of water.

One dam with a catchment of 10 hectares will collect much less water than 10 dams with a catchment of 1 hectare each.

After the main presentation members of the group were asked to present their thoughts. The DG of ABAD Brig (R) Shafaat Cheema gave a very lucid presentation on the activities of his Organization.

The representative from Sungi Development Foundation read out a presentation on Water Harvesting.

I (Sardar Taimur Hyat-Khan) requested to be allowed to present an informal discussion of various techniques for using water more efficiently such as:

Earth Sheltered, Ceramic Adobe Construction technology with a by-product of bricks and ceramic tiles. This low-cost construction could provide badly needed houses as well as by-products to line drains and water channels to reduce losses. The technology can also be used to construct ceramic jars for water harvesting on a low cost and possibly safer basis instead of Ferro Cement.

The importance of Organic matter in the soil to conserve water and also recycle domestic, biodegradable waste.

The Wah Garden as a low cost, environment protected structure with a compost bed to conserve moisture and utilize a below-grade (subsoil) irrigation (reticulation) made from second-hand plastic pipes attached to an earthen jar.

Pakistani, Permanent, No-Till bed for growing vegetables with mulch and compost. The bed is a safe environment for earthworms.

All of the above have been tried on a pilot scale in various locations around the Country and have been adapted to our local conditions and climate. This is as opposed to recommended Chinese and Australian methods. These Countries are indeed progressive. However, there is a need to adapt from their wisdom, as they do not share the same longitudes and latitudes as ours.

At the end of the presentation, it was mutually arranged by PM – IUCN – Abbottabad Conservation Strategy (ACS) Support Unit (Sardar Taimur Hyat-Khan), ICIMOD, and IUCN – ERNP that Professor Chalise and Dr. Salim Sial could travel to Abbottabad along with PM ACS, as they were headed that way, to visit one of their sites in Manshera District. Since Professor Chalise was not well and also because it was found that their original program would entail too rigorous a travel schedule it was decided that they could visit NRCP and give a presentation in Abbottabad. I coordinated with IR of NRCP who was ill at his home. IR very efficiently arranged a field trip for the ICIMOD team. This trip took place on the 18th and was to the project area of the NRCP in Kalapani short of Thandiani, Abbottabad District. The ICIMOD/ NRCP team left for the field area at 10.00 am and returned to the ACS office at 12:30 PM. In the meantime, a presentation by the ICIMOD team and NRCP had been arranged in the ACS office in collaboration with PD NRCP. The presentation was attended by:

➔ RPO – SRSC.

➔ Secretary DASB (Abbottabad/ Haripur).

➔ President Ex-Service Men’s Society (Abbottabad).

➔ Representatives of Civil Society.

➔ PD NRCP and his team.

➔ PM – ACS, IUCN (Abbottabad).

The presentations by ICIMOD and NRCP were very well delivered and received. I urged ICIMOD to establish a Training cum Demo facility in collaboration with NRCP in Abbottabad District. I mentioned that Abbottabad is the central point for the entire Hazara Division and a gateway to Azad Kashmir and the Northern Areas.

Sardar Taimur Hyat-Khan Project Manager, Abbottabad Conservation Strategy (ACS), IUCN.

ĀB-ANBĀR “Water Reservoir” History. 6

The term ‘‘Āb-anbār’’ is common throughout Iran as a designation for roofed underground water cisterns. In Turkmenistan, the term ‘Sardāba’ is found for similar structures.7 Early Islamic sources in Arabic appear to use the words ‘Eṣṭaḵr’ for a Covered Tank or Cistern.8

The ‘‘Āb-anbār’’ was one of the constructions developed in Iran as part of a water management system in areas reliant on permanent (Springs and ‘Qanāts’) or on Seasonal (Rain) Water. A Settlement’s capacity for storing water ensured its survival over the hot, dry season when even the permanent water supply would diminish. Private Cisterns were filled from ‘Qanāts’ (man-made underground channels) during the winter months, before the floods, while surplus flood water could often be stored in open tanks, as well as in the large, public, covered Cisterns.9 Water was brought to the Cisterns by special channels leading from the main ‘Qanāt’ or holding tanks and was controlled by sluice gates. The ‘Āb-anbār’, a ventilated storage chamber, could then provide cool water throughout the summer months. Often rooms or pavilions were built within the complex of the Cistern to provide a comfortable resting place as well.

6 http://www.iranicaonline.org/articles/ab-anbar-i-history

7 See, e.g., N. S. Grazhdankina, Stroitel’nye materialy sardob Turkmenistana, Izvestiya Akademii Nauk Turkmenistanskoi SSR, 1954, no. 4; G. Pugachenkova, Puti razvitiya arkhitektury yuzhnogo Turkmenistana pory rabovladeniya i feodalizma, Moscow, 1958, pp. 243, 394.

8 Le Strange, Lands, pp. 276, 285); and in 14th to 16th-century texts, maṣnaʿ can be understood as designating a Cistern (Jāmeʿ al-ḵayrāt, p. 28; Vaqfnāma, p. 875; Tārīḵ-e ǰadīd-e Yazd, p. 129

9 Wulff, Crafts, p. 258; Pugachenkova, Puti, p. 243.

While private houses may have had their own cisterns, filled in turn from the ‘Qanāts’ or streams, in desert towns like Yazd or Ṭabas. The more noteworthy and elaborate structures were built for public use, often as part of a ‘Waqf’ (Charitable Trust), within towns as well as on caravan routes.10

Two types of structures have been noted, a cylindrical reservoir with a dome and a rectangular one supported by piers or pillars.11 Each was marked by a portal, often with an inscription giving the name of the benefactor (builder or repairer) and the date.12 The portal opened into a steep, barrel-vaulted passageway, leading down to the reservoir.

Although a detailed study of all variations of construction techniques of the ‘Āb-anbār’ in Iran still remains to be done, Grazhdankina’s analyses of similar structures in Turkmenistan, as well as observations by Beazley, Wulff, Siroux, and Sotūda (see below), allow a general outline of the technique. The prime objective in constructing an ‘Āb-anbār’ is to provide a totally waterproof container for a large volume of water while allowing for proper ventilation and access. The excavation was lined with over-fired brick set into a sand and clay mixture. It was then covered with a layer (about 3 cm) of waterproof mortar, ‘Sārūǰ’.13 Larger cisterns were often lined with an additional double layer of bricks, covered with another layer of ‘Sārūǰ’ of slightly different composition, and finished with a hard plaster coat.

The early history of covered cisterns in Iran has not been studied, although it is possible that a major elaboration of construction techniques may have taken place during the Parthian and Sasanian periods when water management constructions (Dams, Weirs, ‘Qanāts’) were built extensively. The geographers of the 10th Century CE apparently described a fully functioning system of Cisterns. The Ardestān desert road, as well as the road from Isfahan to Nāʾīn, was lined with open tanks and domed Cisterns. In fact, these domes often served as the only sure markers on desert routes. ʿAżod-al-dawla (A. D. 943-89) built an enormous vaulted Cistern at Eṣṭarḵr.

Investigations in the ceramicists’ quarter of 11th-12th Century CE, Marv, have revealed a Cistern located in close proximity to the Mausoleum of Mohammad b. Zayd. Its cylindrical reservoir had a 6.1 m diameter and was apparently ventilated by a pair of window-like openings. Its covering has not survived or may not have existed. The Cistern next to the ‘Ribāṭ al-Taḥmalaǰ’, datable by its brick size to the same period and covered by a dome (17 m in diameter and 8 m deep), had a capacity of 150,000 liters.14 Similar structures have been found recorded by Masson on the major desert routes of Central Asia and Turkmenistan, though most extant examples are of a considerably later date. The Cistern associated with the 861 AH/ 1456 CE Mosque at Anaw is 6,5 m in diameter and was fed by three channels.

10 See e.g., A. U. Pope and E. Beaudouin, “City Plans,” in Survey of Persian Art, pp. 1391-1410.

11 See M. Siroux, Caravansérails d’Iran et petites constructions routiers, MIFAO, Cairo, 1949.

12 See, e.g., examples in H. Narāqī, Āṯār-e tārīḵī-e šahrestānhā-ye Kāšān o Nāṭanz, Tehran, 1347 Š./1968.

13 See Grazhdankina, Materialy, for specific analyses of the mortar.

14 Pugachenkova, Puti, pp. 244, 394.

Regional surveys of the Yazd and Kāšān regions have listed scores of ‘Āb-anbārs’, located either within settled areas or along caravan routes. While there are one or two earlier ones, most are dated or datable to the 18th and 19th centuries CE.15 The earliest dated ‘Āb-anbār’ is in Yazd, behind the Masǰed-e ǰāmeʿ, and is dated 878 AH/ 1473 CE.16 ‘Āb-anbārs’ of the Safavid and later periods were built with two or more ‘Bādgīr’ (Ventilating Towers).

The ‘Āb-anbār’ of the ‘Moṣallā’ at Nāʾīn, most likely a Nineteenth-Century CE building, illustrates the typical use of the Towers for the ventilation, as well as the relationship of the cool room pavilion to the ‘Āb-anbār’. The ‘Āb-anbār’ of Ḥāǰǰī Syed Ḥosayn Sabbāḡ in Kāšān dated by its inscription 1240 AH/ 1824 CE is a more elaborate example of a rectangular Hypostyle type. Built within the main Bazaar, it has a large portal decorated with Moqarnas and glazed brick and tile inlay. A set of pavilions or rooms built above the reservoir and cooled by it has separate access from a series of workshops.17 The use of ‘Bādgīrs’ was particularly well developed in Yazd, where there are several ‘Āb-anbārs’ with four ‘Bādgīrs’ as well as the famous ‘Āb-Ānbāršaš-Bādgīrs’ with six.

ĀB-ANBĀR “Water Reservoir” Construction. 18

Cisterns are built in towns and villages throughout Iran, as well as at crossroads, Caravan ‘Saray’s’, and ‘Ribāṭ’ (Hospices). While Town Cisterns may be filled with rainwater or from ‘Qanāts’, most ‘Āb-anbārs’ along caravan routes are filled from the spring torrents of nearby streams; during the dry season gradient weirs are constructed in the stream bed in order to divert water to the cisterns when the winter snows melt and the streams rise. The use of two or more Cisterns becomes necessary when the volume of water is large. As one Cistern becomes full, the water collecting behind the Weir can be directed into a second Cistern by diverting it into a second channel dug alongside the first, as this channel is opened and the other closed off. Should this Channeling system fail to draw off a sizable enough volume, the water would built up behind the Weir and eventually destroy it.

15 See Narāqī, Āṯār-e tārīḵī; Tārīḵ-e ǰadīd-e Yazd; Jāmeʿ-e Mofīdī in bibliog.

16 Ī. Afšār, Yādgārhā-ye Yazd I, Tehran, 1348 Š./1969, fig. 166.

17 Narāqī, Āṯār-e tārīḵī, pp. 306-308; Siroux, Anciennes voies et monuments, p. 125.

18 http://www.iranicaonline.org/articles/ab-anbar-ii-construction

Mode of Construction.

Cisterns built inside private dwellings are usually square or rectangular; public Cisterns in towns or along the caravan routes are generally round. While the former has a flat roof and is often built into the foundation of the house, the latter has a distinctive hemispherical or almost conical roofing.

Water remains quite cool inside the Cistern since it is generally built beneath ground level and is insulated by very thick walls. In most parts of Iran, but particularly in the south, one or more ‘Bādgīr’ (Ventilation Towers) is built along the edge of the Cistern’s roof, directly on the tank wall and connected by a duct to the upper part of the Cistern chamber under the domed roof. Fresh air entering through these ducts keeps the air inside the Cistern chamber circulating and the water-cooled. The six ventilator Cistern to be found in the city of Yazd is probably the most elaborate example of the type equipped with ventilation chambers. In the case of cisterns with domed or conical roofs, the center of the roof is sometimes pierced, and a short ventilation chamber made of brick is built directly over the Cistern chamber. A duct inside the ventilation chamber leads from the openings or slats (that catch the breeze on top) directly inside the roof, again circulating air inside the Cistern chamber. The height of these ventilation chambers is generally about one meter, though some can occasionally be seen that reach a height of two or even three meters.

Construction. Materials used consist essentially of stone or baked brick with lime-mortar and plaster. After the pit that will house the Cistern has been hollowed out, the bottom is covered with slaked lime-mortar. When this floor hardens, the builder erects the tank’s walls, made of baked brick or stone. The bricks are generally plunged in water before being laid. The filling between bricks or stones consists of lime-mortar. After the roofing of brick and slaked lime is laid, the tank’s floor and walls are finished with a coating of plaster.

A type of Cistern called ‘Rīḵtaʾī’ (“Poured,” i.e. made of poured lime-plaster) is considerably cheaper to build. First, the perimeter of the tank’s walls is marked out, and the earth within the wall area is dug out to the desired depth. Next lime-mortar is poured into the square or rectangular trench until it is filled nearly to the ground level. This is left for a week or two until the mortar settles and is solidified. Then the area of earth bounded by the mortar walls is dug out down to the desired floor level. The floor is built by pouring lime-mortar; and, finally, when the walls and floor are dry, they receive a coat of plaster.

Plaster is an indispensable material in the construction of the Iranian Cistern, since the essential function, containment of water is achieved by the water tightness of the plaster. The type of plaster most commonly used, called ‘Sārūǰ’, is a compound from six parts clay, four parts lime, one part ash, and an amount of ‘Lūʾī’ sufficient to keep the compound from cracking; this last consisting of the seeds and pods of an extremely soft and pliable species of the reed. The first step in the preparation of this plaster is the mixture of the clay and lime, to which water is added. All of this is made into a relatively hard, clayey substance which is worked for one or two days. Next, the ashes and ‘Lūʾī’ are pounded into this mixture until the various components have been thoroughly blended. This pounding is done with wooden sticks about 10 cm in diameter and one meter long, one end of which has been tapered to serve as a handle. This last step is important because the more the mixture is pounded and kneaded, the more durable it is. When the plaster compound is ready, it is spread on the walls and the floor of the Cistern with a trowel. The next step is to score the plaster surface with a lentil-shaped stone that fits in the palm of the hand and is called a ‘Mohra’ (“bead”). This scoring goes on for several days until the walls and the floor of the tank begins to perspire, a sign that the components in the plaster are holding together fast. Only then is the Cistern filled with water.

Drawing Water.

Cisterns may be provided with a tap. When the place for the tap is reached in the course of construction, an additional pipe for it is built into the wall; and a plaster compound (half clay and half lime) called ‘Gel-e Harāmzāda’ (“Bastard clay”) is pounded with the feet into the space above the pipe.

Water is taken from this type of Cistern by means of a separate chamber, containing a staircase, about as deep as the adjoining tank chamber. The stairs are wide enough so that persons going up and down with buckets, gourds, or leather bottles will not get in each other’s way. Two, three, or even more taps are sometimes installed. A few Cisterns have been observed to have two separate stairs on opposite sides. In the case of the cisterns built alongside roadways, however, the normal procedure is to construct the staircase within the Cistern chamber itself, so that the water is drawn directly from the tank. An ancient device called ‘Cark e Cah’ was also used in places.

Capacity:The capacity of the traditional cylindrical Cistern varies generally from 300 to 3,000 m3. This upper limit is dictated by the fact that the maximum diameter allowed by the method of construction is about 20 m. If the depth of the tank is up to 10 m, its capacity would be about 3,000 m3. In a few localities, the cisterns have an even greater capacity, and some exceptional examples have been cited as able to hold up to 100,000 m3. These are not round tanks, however, but square or rectangular cisterns with columns placed in the middle of the tank chamber in one or two rows. These support a roof consisting of a series of domes or barrel-vaults.ii

Practical Advantages to Ground Water Harvesting:19

The advantages of groundwater harvesting are plentiful, and many can be considered practicalities. First, groundwater harvesting is not subject to any type of public regulation, including outside utility control or pipeline interruptions that may occur due to natural disasters. Even when the power goes out, your resources will not be affected. Since many groundwater harvesters live in rural areas, the process also is helpful in dealing with issues unique to such a lifestyle. These include the reduction of the mosquito population in damp breeding grounds and immediate availability to water if a fire needs to be put out. It also is able to naturally cool buildings and can add health benefits to those with compromised immunity.

Advantages In Quality:

The quality of harvested water cannot be beaten. It is collected in its pure, natural form, which makes it free of chemicals often found in city ordinance water. It is also free to the harvesters, reducing monthly costs with the elimination of a water bill. It is also sustainable and naturally soft due to an absence of dissolved minerals and common urban contaminants

Disadvantages:

One distinct disadvantage of harvesting groundwater is the effort it takes to do so. A specific protocol must be followed to keep water safe, clean, and convenient. These include designating a catchment area (usually a rooftop) to collect the rain and then organizing pipes or channels to route the water from the roof into ground-level storage containers. Your roof also will need a diversion system to keep the water pure and access to filtration so natural light is able to purify it fully.

19 https://www.hunker.com/12003208/advantages-and-disadvantages-of-ground-water-harvesting

Making the Choice:

Further disadvantages depend upon the region. If you live in an area that is very rainy on a regular basis, your groundwater catchments are fairly simple and straightforward. However, in much of the country, rainy seasons are much more unpredictable, leaving residents without an ample supply of water at times. Researching the chemicals currently found in local water, as well as gleaning advice from neighbors and companies specializing in rainwater catchments in your area can help you make an informed decision as to whether or not a groundwater system will outweigh the disadvantages for you.

How Much Water can be Harvested?

The total amount of water that is received in the form of rainfall over an area is called the rainwater endowment of that area. Out of this, the amount that can be effectively harvested is called the water harvesting potential.

Water Harvesting Potential = Rainfall (mm) x Collection efficiency

The collection efficiency accounts for the fact that all the rainwater falling over an area, cannot be effectively harvested, because of evaporation, spillage, etc. Factors like the runoff coefficient and the first-flush wastage are taken into account when estimating collection efficiency.

The following is an illustrative theoretical calculation that highlights the enormous potential for rainwater harvesting. The same procedure can be applied to get the potential for any plot of land or rooftop area, using rainfall data for that area.

Consider a building with a flat terrace area of 100 sq. m. The average annual rainfall in Abbottabad is approximately 2,673 mm. In simple terms, this means that if the terrace floor is assumed to be impermeable, and all the rain that falls on it is retained without evaporation, then, in one year, there will be rainwater on the terrace floor to a height of 2,673 mm.

Area of plot = 100 sq. m.

Height of rainfall = 2.673 m (2,673 mm )

Volume of rainfall = Area of plot x Height of rainfall over the plot = 100 sq. m. x2.673 m

= 267.3 cu. m. (267,300 l)

Assuming that only 50% of the total rainfall is effectively harvested,

Volume of water harvested = 133,650 liters (267,300 liters x 0.5)

This volume is about 3.66 times the annual drinking water requirement of a 10-member family.

The average daily drinking water requirement per person is 10 liters.

Area of the catchment (m2) x Amount of rainfall = Volume of water received (m3).

Types of Water Harvesting Systems:

There are two general types of rainwater catchment systems - "active" or "passive". Most professionally installed systems incorporate aspects of both to maximize the water conserved. Active rainwater catchment refers to systems that actively collect, filter, store, and reuse water. The storage is usually the most visual aspect of an active system (i.e. large tanks), but they also generally incorporate pumps, and sometimes filters that require electricity (e.g. ultraviolet lights). These are active components that require regular ongoing maintenance to run efficiently and effectively.

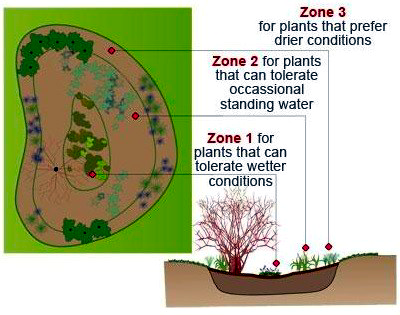

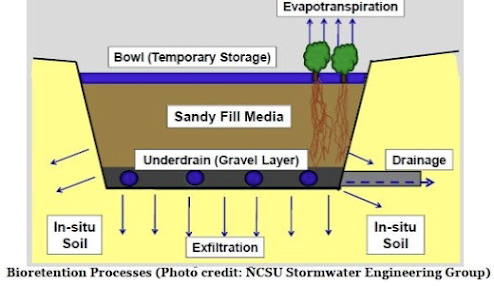

In comparison, passive harvesting systems incorporate no mechanical methods of collecting, cleaning, and storing rainwater. The intent of passive rainwater management is to create areas to contain waters until they can naturally be absorbed into the land. Vegetative swales, dry creek beds, and pervious concrete or pavers are types of passive collections systems. Passive systems can be relatively inexpensive and are generally simple to design and build.20

20 http://www.harvesth2o.com/passive_active.shtml

Broadly, rainwater can be harvested for two purposes:

➔ Stored for ready use in containers above ground or below ground

➔ Charged into the soil for withdrawal later (groundwater recharging).

Catchments:

The catchment of a water harvesting system is the surface that receives rainfall directly and contributes the water to the system. It can be a paved area like a terrace or courtyard of a building or an unpaved area like a lawn or open ground. Temporary structures like sloping sheds can also act as catchments.

Conduits:

Conduits are the pipelines or drains that carry rainwater from the catchment or rooftop to the harvesting system. Conduits may be of any material like galvanized iron (GI), or materials that are commonly available.

Runoff:

Runoff is the term applied to the water that flows away from a catchment after falling on its surface in the form of rain. Runoff can be generated from both paved and unpaved catchment areas of buildings.

The nature of the catchment determines the quantity of runoff that occurs from the area. For example, about 70 % of the rainfall that occurs over the tiled surface of a terrace would flow as runoff while only 10 % of the rainfall on a wooded or grassy area would flow, the rest being retained on the surface and getting percolated into the ground.

From the point of view of quality, runoff can be divided into two types: runoff from paved surfaces (e.g., roofs and courtyards) and runoff from unpaved surfaces (e.g., lawns and playgrounds).

Quality of runoff from paved surfaces is better since runoff from unpaved surfaces may have bacterial or other contamination. If water is to be stored for drinking purposes, it is advisable that only runoff from paved surfaces is used for the purpose.

Storage Facility:

Rainwater can be stored in any commonly used storage containers like RCC, or masonry water tanks. Some maintenance measures like cleaning and disinfecting are required to ensure the duality of water stored in the container.

Many different types of containers are in use for storage purposes from used oil drums to polyethylene tanks. However, according to an ILO publication “Your Health and Safety at Work. Male and Female Reproductive Health Hazards in the Workplace”, polyethylene is “suspected” to cause cancer in human beings. The word suspected is further elaborated to mean where a substance shows inconclusive evidence of causing cancer in human beings but is confirmed in animals. Thus it is safer to avoid the use of polyethylene tanks. Secondly, the transportation of large-size containers is restricted.

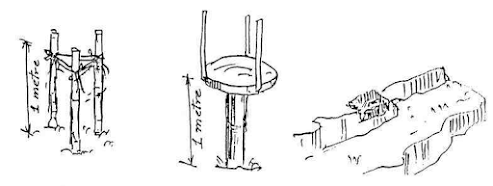

Therefore, a simple tried and tested alternate is proposed. This consists of Pre-Cast RCC Rings that are normally used in lining wells. The rings of 3 – 4 – or 5 feet diameter are stacked on each other to a specified height. The intervention has been displayed by me in the Akhter Hameed Khan National Center for Rural Development (NCRD) at Chak Shahzad, Islamabad, Pakistan. Here a series of plastered and un-plastered tanks demonstrate an affordable and quickly set up a tank that is more permanent and carries the added advantage of maintaining water temperature. This is not so in the case of polyethylene or fiberglass tanks where summer temperatures cause stored water to heat up to uncomfortable levels thus restricting use. Thirdly, the use of concrete is very common in the many parts of the Country in the shape of hollow and solid blocks. Gravel is available in plenty and sand is readily procured. Communities can be persuaded to prepare the rings themselves after training and construct them at conveniently located sites, thereby stimulating local economies. Transportation costs will be reduced and storage till erection will not be a problem.

Recharge Facility:

Alternative to storing, rainwater may be charged into the groundwater aquifers. This can be

done through any suitable structures like dug-wells, bore-wells, recharge trenches and recharge pits.

8.12 Methods of Harvesting Water:

There are two broad approaches to harvesting water:

1. Storing rainwater for direct use.

2. Recharging groundwater aquifers.

Storing Rainwater for Direct Use:

Rooftop harvesting has been practiced for ages, and even today it is practiced in many places throughout the world. In some cases, the rooftop harvesting system is a little more a split pipe or bamboo directing runoff from the roof into an old oil drum placed near the roof.

Generally, runoff from only paved surfaces is used for storing, since it is relatively free of bacteriological contamination. Drainpipes that collect water from the catchment (rooftop) are diverted to the storage container To prevent leaves and debris from entering the system, mesh filters should be provided at the mouth of the drain pipe. Further, a first-flush device should be provided in the conduit before it connects to the storage container. If the stored water is to be used for drinking purposes, a sand

filter should also be provided. A grill prevents debris from entering the drainpipe.

Coarse Mesh (Grill) prevents Passage of Debris.

An underground RCC/ Masonry Tank can be used for storage of the rainwater. The tank can be installed inside the basement of a building or outside the building. Pre-Cast, Concrete Rings used commonly for well lining and readily available in many parts of the Country, can be stacked to construct a tank and can be installed above the ground.

Each tank must have an overflow system for situations when excess water enters the tank. The overflow can be connected to the drainage system.

Design of Storage Tank:

The quantity of water stored in a water harvesting system depends on the size of the catchment area and the size of the storage tank. The storage tank has to be designed according to the water requirements, rainfall, and catchment availability.

First Flush Device:

A first-flush device is a valve or a simple device that is used to ensure that runoff from the first spell of rain is flushed out and does not enter the system. This needs to be done since the first spell of rain carries with it a relatively larger amount of pollutants from the air and catchment surface.

Design Parameters for Storage Tanks:

1. Average annual rainfall.

2. Size of the catchment.

3. Drinking water requirement.

Suppose the system has to be designed for meeting the drinking water requirement of a 5-member family living in a building with a rooftop area of 100 sq. m. The average annual rainfall in the region is 600 mm. The daily drinking water requirement per person (drinking and cooking) is 10 liters.

We shall first calculate the maximum amount of rainfall that can be harvested from the rooftop:

Following details are available:

Area of the catchment (A) = 100 sq. m.

Average annual rainfall (R) = 600 mm (0.61 m) Runoff coefficient (C) = 0.85

Annual water harvesting potential from 100 sq. m. roof = Ax R x C

= 100 × 0.6 × 0.85 = 51 cu. m. (51,000 liters)

The tank capacity has to be designed for the dry period, i.e., the period between the two consecutive rainy seasons. With a monsoon extending over four months, the dry season is of 245 days.

Drinking water requirement for the family (dry season) =245 × 5 × 10 = 12,250 liters

As a safety factor, the tank should be built 20 % larger than required, i.e., 14,700 liters. This tank can meet the basic drinking water requirement of a 5-member family for the dry period.

Runoff Coefficient:

Runoff coefficient is the factor that accounts for the fact that all the rainfall falling on a catchment cannot be collected. Some rainfall will be lost from the catchment by evaporation and retention on the surface itself.

Table: Runoff coefficients for various surfaces:21

Type of Catchment Coefficients

Roof Catchments

-Tiles 0.8 – 0.9

- Corrugated metal sheets 0.7 – 0.9

Ground surface coverings

- Concrete 0.6 – 0.8

- Brick pavement 0.5 – 0.6

Untreated ground catchments

➔ Soil on slopes less than 10 % 0.0 – 0.3

- Rocky natural catchments 0.2 – 0.5

Quality of Stored Water:

Rainwater collected from rooftops is free of mineral pollutants like fluoride and calcium salts, which are generally found in groundwater. But, it is likely to be contaminated with these types of pollutants.

1. Air pollutants.

2. Surface contamination (e.g., silt, dust).

Measures to Ensure Water Quality:

All these types of contamination can be prevented to a large extent by ensuring that the runoff from the first 20 mm of rainfall is flushed off.

Most of the debris carried by. the water from the rooftop i.e. leaves, plastic bags, and paper pieces is arrested by the grill net terrace outlet for rainwater. Remaining contaminants like silt and blow dirt can be removed by sedimentation (settlement), and filtration.

Contrary to popular belief, water quality improves overtime during storage in the tank because impurities settle in the tank if the water is not disturbed. Even pathogenic (harmful) organisms gradually die out due to storage.

Additionally, biological contamination can be removed by disinfecting the water. Many simple methods of disinfecting are available which can be done at a domestic level.22

Recharging Groundwater Aquifers:

In places where the withdrawal of water is more than the rate of recharge, an imbalance in the groundwater reserves are created. Recharging of aquifers are undertaken with the following objectives:

• To maintain or augment natural groundwater as an economic resource.

• To conserve excess surface water underground.

• To combat progressive depletion of groundwater levels.

• To combat unfavorable salt balance and saline water intrusion.

Design of an Aquifer Recharge System:

To achieve the objectives it is imperative to plan out an artificial recharge scheme in a scientific manner. Thus it is imperative that proper scientific investigations be carried out for the selection of a site for artificial recharge of groundwater.

The Proper Design Will Include the Following Considerations:

Selection of site: The Recharge structures should be planned out after conducting proper hydrogeological investigations. Based on the analysis of this data (already existing or those collected during the investigation) it should be possible to:

• Define the sub-surface geology.

• Determine the presence or absence of impermeable layers or lenses that can impede percolation.

• Define depths to the water table and groundwater flow directions.

• Establish the maximum rate of recharge that could be achieved at the site.

21 Source: Pacey, Arnold and Cullis, Adrian 1989, Rainwater Harvesting: The collection of rainfall and runoff in rural areas. Intermediate Technology Publications. London, pg. 55

22 Specifications for drinking water are given by IS: 10500 and World Health Organization (WHO).

Source of Water Used for Recharge:

Basically, the potential of rainwater harvesting and the quantity and quality of water available for recharging, have to be assessed.

• Engineering, construction, and costs.

• Operation, maintenance, and monitoring.

Various kinds of recharge structures are possible which can ensure that rainwater percolates in the ground instead of draining away from the surface. While some structures promote the percolation of water through soil strata at a shallower depth (e.g., recharge trenches, permeable pavements), others conduct water to greater depths from where it joins the groundwater (e.g., recharge wells).

At many locations, existing features like wells, pits, and tanks can be modified to be used as recharge structures, eliminating the need to construct any structures afresh.

A few commonly used recharging methods are explained here. Innumerable innovations and combinations of these methods are possible.

Bore-Wells / Dug-Wells:

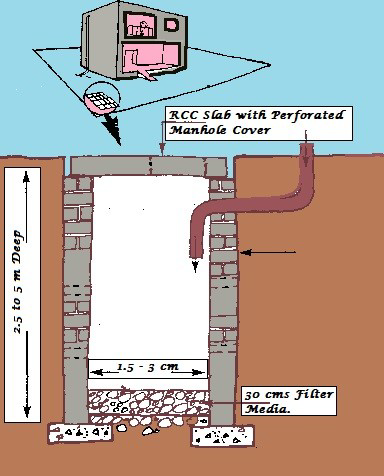

Rainwater that is collected on the rooftop of a building is diverted by drainpipes to a settlement or filtration tank, from which it flows into the recharge well (bore-well or dug-well).

If a bore-well is used for recharging, then the casing (outer pipe) of the bore-well should preferably be a slotted or perforated pipe so that more surface area is available for the water to percolate. Developing a bore-well would increase its recharging capacity (developing is the process where water or air is forced into the well under pressure to loosen the soil strata surrounding the bore to make it more permeable).

Recharge Bore-Well:

If a dug-well is used for recharge, the well lining should have openings (weep-holes) at regular intervals to allow the seepage of water through the sides. Dug-wells should be covered to prevent mosquito breeding and entry of leaves and debris. The bottom of the recharge dug-wells should be desilted annually to maintain the intake capacity.

Precautions should be taken to ensure that physical matter in the runoff like silt and floating debris do not enter the well since it may cause clogging of the recharge structure. It is preferred that the dug-well or bore-well used for recharging be shallower than the water table. This ensures that the water recharged through the well has a sufficient thickness of soil medium through which it has to pass before it joins the groundwater. Any old well which has become defunct can be used for recharging since the depth of such wells is above the water level.

Quality of Water Recharged:

The quality of water entering the recharging wells can be ensured by providing the following elements in the system:

1. Filter mesh at the entrance point of rooftop drains.

2. Settlement chamber.

3. Filter bed.

Settlement Tank:

Settlement tanks are used to remove silt and other floating impurities from rainwater. A settlement tank is like an ordinary storage container having provisions for inflow (bringing water from the catchment), outflow (carrying water to the recharge well), and overflow. A settlement tank can have an unpaved bottom surface to allow standing water to percolate into the soil.

Apart from removing silt from the water, the desilting chamber acts as a buffer in the system. In case of excess rainfall, the rate of recharge, especially of bore-wells, may not match the rate of rainfall. In such situations, the desilting chamber holds the excess amount of water till it is soaked up by the recharge structure.

Options for Settlement Tank.

Any container with an adequate capacity of storage can be used as a settlement tank. Generally, masonry or concrete underground tanks are preferred since they do not occupy any surface area. Old disused tanks can be modified to be used as settlement tanks

For overground tanks, pre-fabricated Concrete Rings or Ferro-Cement tanks can be used. Pre-fabricated tanks are easy to install.

Design Parameters for Settlement Tank

For designing the optimum capacity of the tank, the following aspects have to be considered:

1. Size of the catchment

2. Intensity of rainfall

3. Rate of recharge

Since the desilting tank also acts as a buffer tank, it is designed such that it can retain a certain amount of rainfall, since the rate of recharge may not be comparable with the rate of runoff. The capacity of the tank should be enough to retain the runoff occurring from conditions of peak rainfall intensity based on a 25-year frequency. The rate of recharge in comparison to runoff is a critical factor.

However, since accurate recharge rates are not available without detailed geo-hydrological studies, the rates have to be assumed. The capacity of the recharge tank is designed to retain runoff from at least 15 minutes of rainfall of peak intensity.

Suppose the following data is available:

Area of rooftop catchment (A) = 100 sq. m.

Peak rainfall in 15 min (r) = 25 mm (0.025 m)

Runoff coefficient (C) = 0.85

= A x r x C

= 100 × 0.025 × 0.85

= 2.125 cu. m. (2,125 liters).

Then, the capacity of the desilting tank = 2,500 Liters.

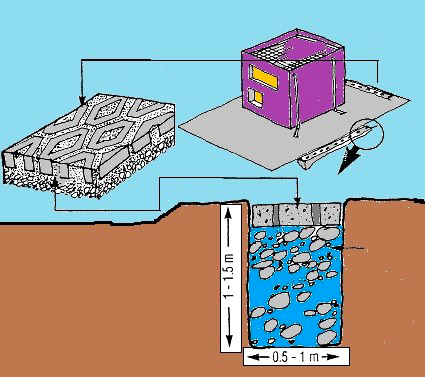

Recharge Pits.

A recharge pit is a pit 1.5 m to 3 m wide and 2 m to 3 m deep. The excavated pit is lined with a brick/stone wall with openings (weep-holes) at regular intervals. The top area of the pit can be covered with a perforated cover. The method for designing a recharge pit is similar to that for a settlement tank.

Soak Aways:

A Soakaway is a bored hole of up to 30 cm diameter drilled in the ground to a depth of 3 to 5m. The Soakaway can be drilled with a manual auger unless hard rock is found at a shallow depth.

The borehole can be left unlined if a stable soil formation like clay is present. In such cases, the Soak away may be filled up with media like brickbats. In unstable formations like sand, the Soak away should be lined with a Pre-cast Cement Rings to prevent collapse.

A small sump is built at the top end of the Soakaway where some amount of runoff can be retained before it Infiltrates through the soakaway. Since the sump also acts as a buffer in the system, it has to be designed on the basis of expected runoff as described for settlement tanks.

Simple; Low-Cost Surface Rain Water Harvesting.

A Geomembrane Lining with Mazri (Date Palm Foliage Sindh/ Baluchistan) Cover would be of great advantage. This is a self-help Project and can be augmented with the Provision of appropriate Geomembrane.

Surface Water Harvesting Pre-Cast Concrete Rings; GI Cover, 2” Faucet.

Terraced Area: Mung, Haripur, Hazara.

Recharge Trenches:

Recharging through recharge trenches, recharge pits and Soakaways is simpler compared to recharge through wells. Fewer precautions have to be taken to maintain the quality of the rainfall-runoff. For these types of structures, there is no restriction on the type of catchment from which water is to be harvested, i.e., both paved and unpaved catchments can be tapped. A recharge trench is simply a continuous trench excavated in the ground and refilled with porous media like pebbles, boulders.

Design of a Recharge Trench:

The methodology of the design of a recharge trench is similar to that for designing a settlement tank. The difference is that the water-holding capacity of a recharge trench is less than its gross volume because it is filled with a porous material. A factor of the loose density of the media (void ratio) has to be applied to the equation. The void ratio of the filler material varies with the kind of material used, but for commonly used materials like brickbats, pebbles, and gravel, a void ratio of 0.5 may be assumed. Using the same method as used for designing a settlement tank:

Assuming a void ratio of 0.5, the required capacity of a recharge tank

= (100 × 0.025 × 0.85)/ 0.5

= 4.25 m3 (4,250 liters).

In designing a recharge trench, the length of the trench is an important factor. Once the required capacity is calculated, length can be calculated by considering a fixed depth and width.23

Community Level Water Harvesting System.

Tapping stormwater drains in a community-level system is another option as opposed to single home water harvesting units. In this System the entire Community, along with common land is tapped for Water Harvesting, thereby increasing the Net Gain corresponding to the size of catchment. To control the total amount of runoff received by a large scale system, the catchment can be subdivided into smaller parts. A locality-level water harvesting system illustrated in the figure below shows how the runoff from individual houses can be dealt with at the building-level itself, while remaining runoff from the stormwater drain (which drains water from roads and open areas) can be harvested by constructing recharge structures in common areas.

23 http://www.rainwaterharvesting.org/urban/Design_Recharge.htm

Water Distillation:

Aqua-Pure Evaporator/ Crystallizer System design takes advantage of the most recent innovations in heat exchanger technology, incorporating a compact state-of-the-art plate re-boiler exchanger that utilizes very low approach temperatures and high re-boiler brine flow rates, maximizing the thermal transfer efficiency while minimizing fouling tendencies.

Pre-manufactured compact modules range in capacity from 10usgpm to 400usgpm and can be moved from site to site.

Systems recover 97% of the energy required to distill water (<25 BTU/ lb wastewater feed). This results in very low energy consumption, typically 60-70kW/ 1000usg of wastewater feed.

Powered from conventional electricity, steam, or waste energy. Evaporators are designed to handle wastewater with varying influent characteristics while maintaining consistently high quality distilled water output.

Configurations include:

Mechanical Vapour Recompression (MVR), Thermo Vapour

Recompression (TVR), Multiple Effect (ME), or a combination.

Zero Liquid Discharge (ZLD) Solutions.

Swenson’s crystallizer expertise allows Aqua-Pure to offer ZLD solutions for our customers. Where required, a Reverse Osmosis (RO) membrane or other system may be supplied ahead of the evaporator system.

Water Retention:

Retention of water for brief periods to either meet immediate needs or allow infiltration into the ground as opposed to Mega Dams is a desirable objective. Firstly it is necessary that we understand the Water cycles.

Mega Dams.

Geology and water in rock masses can be major sources of problems in dam safety. Water seeping in rock masses can affect the safety of dams in essentially two ways: erosion and uplift.

Several dam failures have been attributed to excessive uplift. Earthquakes can be induced by dams. Globally, there are over 100 identified cases of earthquakes that scientists believe were triggered by reservoirs. The most serious case may be the 7.9-magnitude Sichuan earthquake in May 2008, which killed an estimated 80,000 people and has been linked to the construction of the Zipingpu Dam.

Reservoir-Induced Seismicity (RIS):

The most widely accepted explanation of how dams cause earthquakes is related to the extra water pressure created in the micro-cracks and fissures in the ground under and near a reservoir. When the pressure of the water in the rocks increases, it acts to lubricate faults which are already under tectonic strain but are prevented from slipping by the friction of the rock surfaces."

Given that every dam site has unique geological characteristics, it is not possible to accurately predict when and where earthquakes will occur. However, the International Commission on Large Dams recommends that RIS should be considered for reservoirs deeper than 100 meters.

• Depth of the reservoir is the most important factor, but the volume of water also plays a significant role in triggering earthquakes.

• RIS can be immediately noticed during filling periods of reservoirs.

• RIS can happen immediately after the filling of a reservoir or after a certain time lag.

Many dams are being built in seismically active regions, including the Himalayas, Southwest China, Iran, Turkey, and Chile. International Rivers calls for a moratorium on the construction of high dams in earthquake-prone areas.

The South Asian river basins, most of which have their source in the Himalayas, support rich ecosystems and irrigate millions of hectares of fields, thereby supporting some of the highest population

densities in the world.

Rivers are, however, also a source of conflict between countries and people in the region. The question of whether and how to harness rivers for hydropower generation and commercial irrigation is an issue of great concern and a source of controversy. Large-scale water development schemes have in the past contributed to the impoverishment of many river basin communities in South Asia.

However, many governments in the region exaggerate the irrigation and power benefits of large dams and neglect their social, environmental, and economic costs, and continue to promote them as the best option for increasing access to energy and water. Better ways to harness water and generate energy are too often overlooked. Decentralized renewable power supply options, such as off-grid micro-hydropower, biogas plants, solar and wind power – would often be more cost-effective and better suited to supply rural villages with electricity. Supporting poor farmers to trap rain when and where it falls would often be a better investment for rural poverty reduction than the construction of large storage dams.

Our warming climate is changing the Himalayas faster than any other region of the world. The mountains’ mighty glaciers, the source of most large Asian rivers, are melting. Against these dramatic changes, the governments of India, Pakistan, Nepal, and Bhutan are planning to transform the Himalayan rivers into the powerhouse of South Asia. They want to build hundreds of Mega Dams to

generate electricity from the wild waters of the Himalayas.

The dams’ reservoirs and transmission lines will destroy thousands of houses, towns, villages, fields, spiritual sites, and even parts of the highest highway in the world, the Karakoram highway. Technically, run-of-river projects are projects without any storage or pondage. They use the flow of the water in the natural river course, or sometimes through diversions like canals and tunnels, to generate electricity.

They can have many of the typical structures such as dams, weirs, headraces, tailraces, and diversions tunnels. Many Himalayan dams are being classified as the run of river and hence are touted as socially and environmentally benign; this is false. Many run-of-river projects can have serious impacts by disturbing downstream river flows. Some run-of-river projects divert the water into tunnels, leaving downstream sections dry, and thus cause even more severe impacts downstream. Ecological Impacts The Himalayas are recognized as a hotspot of biodiversity.

With a reduction in force of impact of raindrops and soil that is bound with strong roots the process of infiltration of water into the soil is greatly increased. Reduction in wind speed also reduces erosion of soil, thus we not only prevent the erosion of precious topsoil we also gain in water. Ruthless cutting of our Forests has led to decreased infiltration of water and increased soil erosion.

Trees and Afforestation:

Forests occupy a relatively small proportion of the land area in Pakistan (some 3 – 5 %) but nevertheless play a vital role in the country’s economy. Forests remain an important source of fuelwood, grazing land, livelihood, and Government Revenue. Forests also provide multiple ecological services such as watershed protection, soil conservation, biodiversity habitat, and play a vital role in assuring Eco-system resilience (i.e. stability).

The Natural Forest Resource Assessment NFRA classification shows that forest cover is declining in Pakistan.24 Estimated deforestation rate over the 1990-2005 period was 2.1 % or 47 thousand hectares annually. Forest types included in this definition of forests are coniferous forest, riverain, and mangrove forest. It is estimated that the most valuable coniferous forest is declining at the rate of 40,000 hectares annually. Northern Areas and KP have the highest annual rates of deforestation (about 34,000 hectares in Northern Areas and 8,000 hectares in KP). Riverain and mangrove forests are also decreasing at the rate of 2,300 and 4,900 hectares annually. This is an alarming rate given the quite high ecological value of these types of forest Using this classification, the estimated costs of deforestation in Pakistan are between Rs. 206 to 334 million per anum.25

24 NFRA 2004

Forest Eco-System Protection: Economy Generation.

It is, by now, a well-known fact that trees and Forests are the foundation upon which the entire world of renewable natural resources is balanced Man . has interfered in the Natural Forest Eco-System in many ways. Clear cutting and reduction in the forest canopy are the most blatant means of interference. When these activities are curtailed, other less obvious means are used. Removal of forest litter is perhaps the most damaging. This is the first level of the forest food chain. Secondly, it forms the natural habitat for microorganisms that are essential to the dynamics of the ecological cycle. Upland, stony soils have a very slow weathering process and hydro-thermic cycle. With a reduction in the forest canopy, impaction and erosion capacity of raindrops are greatly increased. The absence of an under-story, as found in mixed tree and bush forests, further compounds this situation. The velocity of falling raindrops is curtailed as they strike the trees and filter down to the forest floor. If this does not happen, the soil is struck with higher velocity raindrops and is subject to movement on the surface. Waterbearing particles of soil are aided in erosion capacity. These soil particles act like tiny blades to further erode the nutrient-rich topsoil. Thus even the tertiary-source of nutrients is removed The sources of forest nutrition are:

• Forest Litter that decomposes into Humus.

• Symbiotic bacteria/ micro-organisms/ fungi that fix nitrogen.

• Mineralized topsoil (subjected to weathering).

• Transport of minerals within soil profile (no profile - no transport).

Thus it is obvious that our forest Eco-Systems have been destabilized (preservation of nutrients/ minerals circulated within the soil - vegetation subsystem).

Depleted forest resources with reduced canopy cover and malnourished trees with stunted growth do not serve the purpose that Nature intended them for. Also, natural regeneration and young sapling are the first to suffer. Thus the future of the forest is even bleaker than the present. Rank exploitation of timber resources in a non-sustainable way is the primary cause. However, the populations that live in close proximity to forests have a right to natural resources. They have needs for:

• Fuelwood.

• Fodder

• Building material.

• Income generation.

How is it possible to deny them access to these resources? Motivation by pointing out that it takes years to rebuild nutrient cycling and the attendant harmful effects upon the environment of deforestation are not sufficient to achieve forest protection. Alternates that are viable, cost-effective, and practicable are called for. The question arises do they exist? The answer is a resounding YES!

Seabuckthorn:

"Seabuckthorn is a deciduous shrub and is widely distributed throughout the temperate zones of Asia and Europe and throughout the subtropical zones of Asia at high altitudes."25 The Latin name Hippohae spp. Is used for this shrub that consists of six species and ten subspecies. It thrives from the sea level to 5,200 m. The annual coverage temperature is 0° C to 12° C, though it can survive temperatures as high as 40° C. Minimum temperature tolerance is as low as - 40° C. Annualprecipitation range requirement is 600 to 700 mm as most suitable. Precipitation of300 to 1,000 mm range is acceptable. Soil requirements are well-drained, sandy, or stony soils with a soil pH range of 5.5 to 8.3. Salinity of 1.1 % can be tolerated by the plants.

The plant has a very strong root system with a taproot of 3 m and horizontal roots of 6 to 10 m. Self-propagation through root turions enables the plant to produce 10 to 20 generations. The fruit of this plant contains 60 to 80 % juice. This juice has 200 to 1500 mg per 100 g and is rich in vitamins, sugar organic acids, and amino acids. The fruit contains 3 to 5% pulp oil and 8 to 18 % seed oil, rich in unsaturated acids, B- carotene, and vitamin E. The leaves contain 11 to 22 % crude protein, 3 to 6 % crude fat, and some flavonoids. The fruit can be used to make soft drinks health, food, medicines, and cosmetics

China has a Seabuckthorn Industry with over 100 factories producing over 200 products with a gross value of about US$ 40 million annually. The leaves and tender branches are excellent fodder for sheep, goats, and cattle. In China, 51 species of birds and 29 species of animals are dependent upon this plant as a part of their food chain. Some major benefits of this plant additionally exist. These are:26

• Nitrogen Fixing Capacity: An 8 to 10-year-old Seabuckthorn Forest can fix 180 Kg of nitrogen/ha/year (72 Kg/acre/year or 9Kg/Kanal/year).

• Biomass Production: A 6-year-old Seabuckthorn plantation can produce 18 tons of fuel-wood per hectare. Heat value is 4785.5 calories/ Kg. One ton of wood is equal to 0 68 tons of stand.ard coal

• Erosion Control: In comparison to wasteland a 7-year-old plantation can reduce 99 %runoff and 96 % soil loss.

• Soil Fertility: Nitrogen, phosphorus, and organic contents of soil are greatly increased.

• Companion Tree Growth: Pine and Popular when mixed with Seabuckthorn thrive due to nitrogen fixation and protection from the cover. Chinese results indicate that mixed stands of Pine and Seabuckthorn have 1.3 to 1.7 times higher growth rate.27

• Other Uses: Windbreaks and stream/ riverbank stabilization can be obtained.

Seabuckthorn is propagated from:

• Seed (germination rate 80 to 95 % - 1 Kg seed produces 104 to 133 thousand saplings).

• Hardwood Cuttings: 2-3-year-old shoots, rooting rate is 50 to 70 %.• Softwood Cuttings: & to 10 cm cuttings with several leaves are used and propagated in plastic film houses for 2 years.

• Aerial Seeding: 400 mm rainfall and 6 to 8 days of continuous cloudy and rainy days are required. At germination rates of 1 %, a density of 1 plant per 10 square meters is used. Pre-germination of seed treated with Natural Rooting and Fruiting Hormones are recommended

25 .Feasibility Study of Seabuckthorn Development in Pakistan, Lu Rongsen, ICIMOD (Nepal), MINFAL (Pakistan) 1996.

26 . Dr Abdul Wahid Jas , ra NADR, I NARC, Islamabad .

27. Chinese Success Models of Seabuckthorn Development, A Tour Report, Dr. A.W Jasra NADRI 1996.

Objections:

The unfortunate experiences of Eucalyptus and Wild Mulberry have raised fears of Invasive Species in the minds of many Foresters and NRM specialists. Along with resistance to change, this is causing a delay in the establishment of this plant. To ally some of these fears it is pointed out that Seabuckthorn is a native of Pakistan variety that flourishes here is Hippopchae rhamnoides (turkestanica) This sub-species is suited to arid hot summers and cold winters. About 3,000 hectares of wild Seabuckthorn Forests exist in Baltistan, Gilgit, Chitral, and Swat at altitudes between 2200 to 2800 m. At present afforestation has been carried out in Balochistan and Waziristan (Former FATA).

Comparison.

Having assessed the costs of degradation in Pakistan it is instructive to compare the overall environmental performance with other countries. A number of environmental sustainability indices have been developed to facilitate this process. The most comprehensive and widely quoted measure is the Environmental Sustainability Index (ESI), ESI is a composite index of 21 indicators that cover five broad categories of environmental pressure. The sub-components measure performance in the following areas:28

1. Environmental Systems.

2. Reducing Environmental Stresses.

3. Reducing Human Vulnerability to Environmental Stresses

4. Societal and Institutional Capacity to Respond to Environmental Challenges.

5. Global Stewardship.

As with any other aggregate index, the ESI is not without its shortcomings. Given the lack of information in many countries, the rankings are an approximation of sustainability, based on an aggregation of a wide array of indicators. As a result of high population density, a pollution-intensive industrial structure, a vulnerable natural resource base, and limited capacity to mitigate environmental stress, Pakistan scores the lowest ESI in South Asia.

Pakistan remains relatively more susceptible to land degradation than most nations in the arid zone category. This vulnerability reflects not only the Country’s water scarcity, but it’s ability to cope

with the problem.

28 Global Stewardship. a collaborative venture of the Yale Center of Environmental Law and Policy and CIESIN at Columbia University.

29 Document of the World Bank Report No. 36946-PK Pakistan Strategic Country Environmental Assessment. South Asia Environment and Social Development Unit South Asia Region August 21, 2006.

The loss of forest cover and conversion of forested land to other uses can degrade supplies of freshwater, threatening the survival of millions of people and damaging the environment.30 Watershed conditions can be best improved if forests are managed with human as well as hydrological goals as a priority. Watershed degradation has been recognized in many countries as a serious threat to the environment and to the survival of people living in watershed and downstream areas over the past 20 years. Watershed Management Programs failed to achieve their goals, the study says, because they neglected to consider the needs and behaviors of human beings and instead focused only on conservation aspects of natural resources.

The lack of long term commitment to address underlying causes of forest and watershed degradation also contributed to the failures. Mountainous forested watersheds are the most important freshwater yielding areas in the world, the study says, but they are also the source areas for landslides, torrents and floods."

To prevent or lessen disasters in mountainous terrain, healthy forest cover must be maintained on watersheds that are subject to torrential rainfall. The FAO recommends the development of programs that combine forest protection with zoning, floodplain management and engineering structures to protect people from landslides, debris flows and floods.

The largest and most damaging floods in major rivers are not affected by the extent of watershed forest cover, the agency says, but moderate and localized floods can increase when forests are removed. Healthy upland and riparian forests can keep high levels of sediment from being deposited in rivers, lakes and reservoirs during floods.

The economic value of water must be recognized, the FAO states, and recommends "reducing water subsidies and treating water as a commodity rather than a free good" so that economic incentives can support better watershed management. With economic incentives in place, new management techniques can be attempted, the agency says, such as replacing trees that consume a great deal of water with species that consume less when forests in municipal watersheds are thinned or logged.

Throughout its forests and freshwater report, the FAO team emphasizes enhanced communication with local communities and stakeholders, expanded educational and training programs, and sharing of effective techniques with local residents to increase the conservation of forested watersheds.

30 FAO: Fresh Water Supplies Depend on Healthy Forests.

Watershed Management.

The Four Core Principles of Watershed Management:

1. Watersheds are natural systems that we can work with.

2. Watershed management is continuous and needs a multidisciplinary approach.

3. A watershed management framework supports partnering, using sound science, taking well-planned actions, and achieving results.

4. A flexible approach is always needed.

A watershed management plan should include an overview of the current conditions of the watershed, including physical, chemical, and biological characteristics of the stream network, as well as current land use and potential sources of impairment. The plan will outline the goals of the management plan. These goals will quantify the level of impairment. Next, a plan will provide management strategies through which the impairments will be addressed.

Finally, it will include a time-line for completing watershed management implementation to take place and an estimate of how much the plan will cost to implement.

Define Watershed Plan.

Defining a watershed plan deals with preliminary activities you undertake to start scoping out your planning effort. It includes information on defining issues of concern, developing preliminary goals, and identifying indicators to assess current conditions.

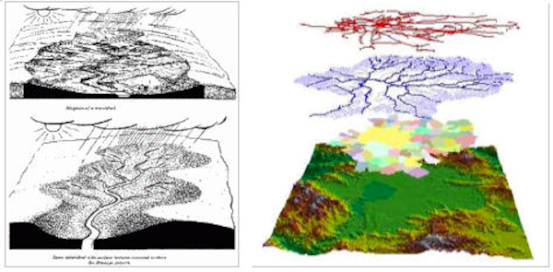

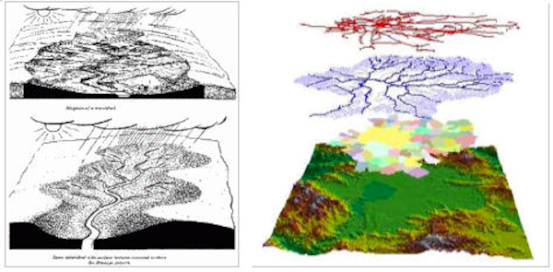

The user can work with the Digital Watershed tool to identify both the geographic region in which their plan will focus and the impairments present in their watershed.

Gather Existing Data. Gathering existing data is the first step in watershed characterization. It includes the collection of information from existing reports and data sets. Users can work with the Digital Watershed Tool to help them identify available data, locate the information, gather and organize necessary data, and determine data needs.

Assess Watershed Conditions ( ATtILA, ReVA). Once all of the existing watershed data has been gathered, the next step is to assess watershed conditions. Assessing watershed conditions will help a user to determine the acceptability of data, identify data gaps, and design a future sampling plan. The user can work with the ATtILA tool to determine land use characteristics and to calculate the number of impervious surfaces in a specific watershed. The user will also work with the ReVA tool to identify potential landscape stressors in their watershed.

Tools that have been developed include the Automated Geospatial Watershed Assessment (AGWA) tool and the Analytical Tools Interface for Landscape Assessments (ATtILA):

• The AGWA tool helps identify and prioritize potential problem areas at the watershed level.

It can evaluate the effects of various land-use changes on water quality and identify locations where impacts are likely to be most significant. Model outputs for streams and upland areas (above the streamside or riparian corridor) can be quantified and mapped for comparison with other data and assessment results. AGWA incorporates two watershed runoff models, the Runoff and Erosion Model (KINEROS2) and the Soil and Water Assessment Tool (SWAT)—into GIS.

ATtILA is a Downloadable ArcView extension that calculates landscape characteristics, riparian characteristics, human stressors, and physical characteristics for a given area using simple, easily accessible data. Digital Watershed provides static layers containing statistics/characteristics for 8 digit watersheds in Digital Watershed, as well as a web-interface to run ATtILA over the web to generate up-to-date summary statistics.

• ATtILA is a user-friendly GIS extension that calculates many common landscape metrics. It is equally suitable across all landscapes, from deserts and forests to urban areas. ATtILA measures four types of characteristics:

o Landscape characteristics, e.g. percentage of grassland cover or number and size of grassland patches